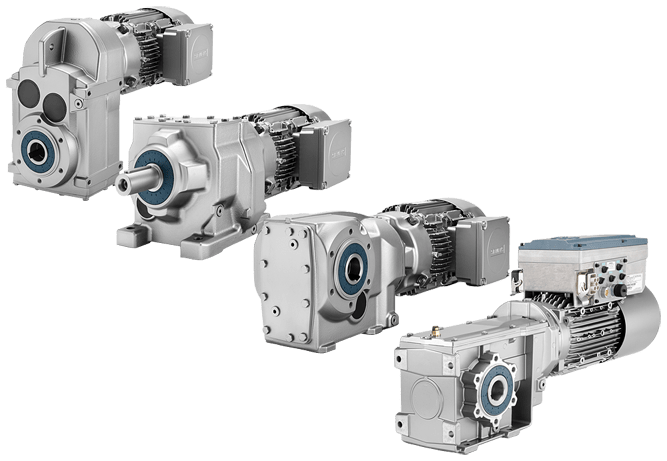

Compact gearboxes are high-quality gearboxes for standard drives. The electric motor is integrated with the gearbox into a single unit (the first gear is directly on the motor shaft). Separate gearboxes for connection to conventional IEC motors can also be supplied on request.

Due to the complexity of the gearboxes’ configuration, they cannot be purchased in our e-shop. Our specialists will be happy to help you make your selection. We will be happy to send you documentation or design a suitable set directly, on request.

Do you want to check some information or find a specific gearbox feature? Browse the Motox or Simogear catalogs.

Our unique form will guide you through the gear configuration and selection and save time for you and our staff. You are a few clicks away from the complete demand.

We will be happy to assist you in selecting a gearbox suited to your application. To do so, we will need a few details in order to provide the right advice:

We will draw up an offer in response to your requirements, including dimensional sketches, prices, delivery dates and detailed technical data. On request, we can also supply 3D models in various formats, or, for example, a report calculating the service life of bearings according to your requirements for the radial and axial forces on the output shaft.

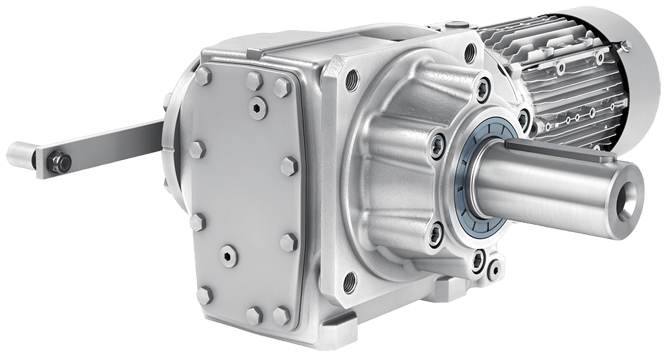

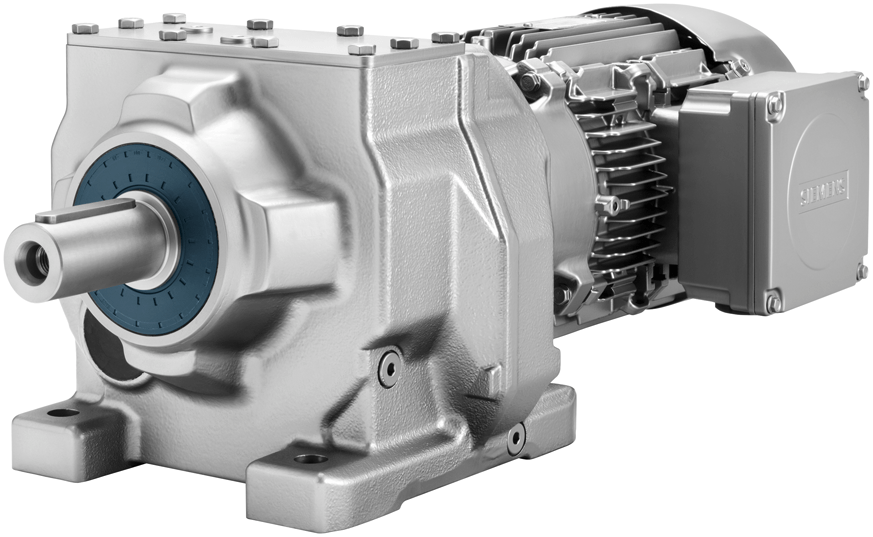

Spur gearboxes are the most widely used gearbox design for all types of standard applications with a solid output shaft in the motor axis.

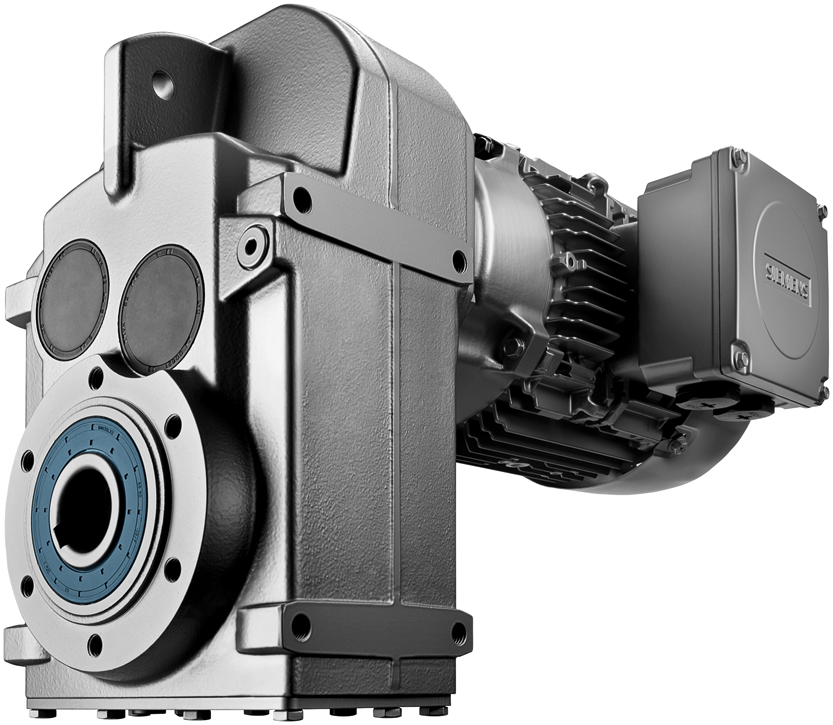

Gearboxes derived from the spur gearboxes, with an output shaft parallel to the motor axis. Suitable for applications where a spur gearbox would be too long, or where a hollow output shaft or a cylindrical one- or two-sided shaft is required.

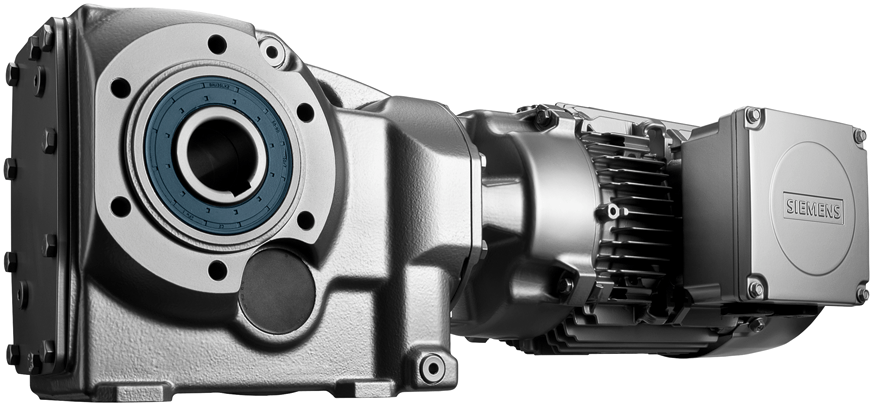

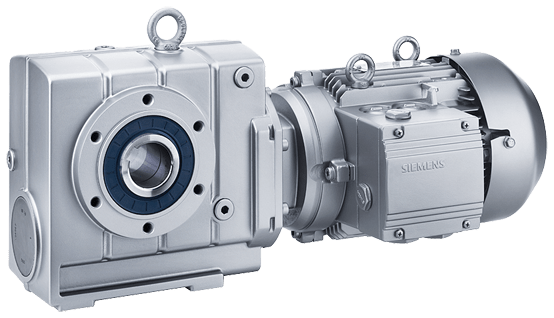

Gearboxes with a combination of spur and bevel gears are very popular due to their very high efficiency. They are suitable for applications that require a hollow or solid (one- or two-sided) output shaft perpendicular to the motor axis.

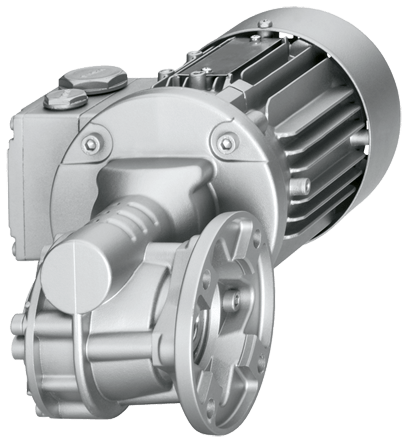

One of the most widespread gearbox designs uses worm gears. The advantages of worm gearboxes are their low cost, very simple design and, where required, self-locking. Their downside is the relatively high torque loss (low efficiency).

Compact worm gearboxes are only supplied with a limited range of outputs and gear ratios. They are suitable for applications that require a hollow or solid (one- or two-sided) output shaft perpendicular to the motor axis. For more demanding applications and high output, we recommend Cavex worm gearboxes.

Gearboxes combining spur and worm gears are cost-effective and torque-resistant. The main disadvantages, compared to the helical-bevel design, are the lower efficiency and smaller range of outputs and gear ratios. They are suitable for applications that require a hollow or solid (one- or two-sided) output shaft perpendicular to the motor axis.

We are an authorised service partner for Motox electric gearboxes (SERCO Partner Siemens).

We offer not only after-warranty and warranty servicing, but also regular maintenance (e.g. oil, seal and filter changes in keeping with the prescribed service intervals).